As manufacturing companies navigate fluctuating demand, complex supply chains, and stringent regulations, streamlining invoice processes and enhancing financial accuracy are imperative. In this article, we’ll explore the critical role of AP optimization in large-scale production environments, from seamless integration with manufacturing operations to efficient cost allocation and robust supplier management. As a manufacturer, disjointed accounts payable processes can strain working capital and hide excessive expenditures across facilities. But with Medius AP automation, you can optimize invoice processing, compliance, and cost controls to drive margins.

Slow Invoice Processing Times

We use high quality equipment that will ensure the accuracy and consistency in each manufacturing part. N recent years, Computer Numerical Control (CNC) machining technology has become pivotal in the development of various industries, especially in military and maritime sectors. With high precision, reproducibility, and manufacturing flexibility, CNC machining plays a crucial role in fabricating accounting strategic components and equipment. Control cables were developed to meet the need for lightweight cable for reliable control in various applications.

Audio, Video and Broadcasting Cables

- Stampli focuses on enhancing invoice processing efficiency for manufacturers through AI-powered tools and collaborative workflows.

- Our system is scalable, so it grows with your business—whether you’re adding new facilities or ramping up production.

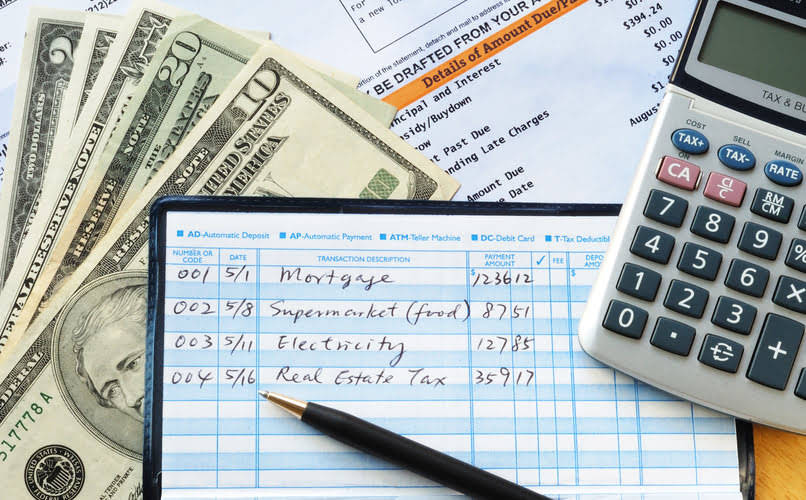

- Electronic Funds Transfer (EFT) is the electronic transfer of money from one bank account to another, commonly used for paying invoices.

- Coordinators can now spend more time optimizing the supply chain rather than managing payment delays, resulting in smoother operations, reduced downtime, and fewer disruptions in the manufacturing process.

The impact of a disrupted supply chain can manufacturing ap technology cascade through every level of production, making effective management of AP processes essential. Here, MetaViewer’s AP automation comes into play, offering an integrated and secure solution that harmonises supply chain operations. One of the major challenges facing the manufacturing industry in terms of accounts payable (AP) automation is managing the complexity of their supply chains. These interactions usually create a purchase order, which is key for accounts payable automation. For these companies, the percentage of invoices based on purchase orders can climb up to a staggering 90% of all invoices received.

Why should I automate my manufacturing purchase-to-pay process?

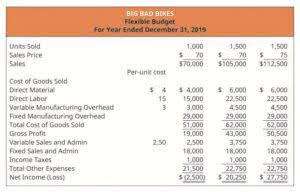

Automated AP systems in manufacturing provide real-time data and analytics, enabling more accurate and timely KPI tracking. By monitoring KPIs, companies can optimize their AP processes and achieve better financial outcomes. Modern AP automation already interlinks with advanced technologies manufacturers are exploring, whether IoT sensors, logistics telematics, predictive analytics or machine learning.

What is the Best AP Automation Software for Manufacturing Companies in 2025?

This process includes data capture, validation, approval routing, and payment authorization. Manual invoice processing can be time-consuming and error-prone, leading to delays and inaccuracies. AP processes in manufacturing include AI in Accounting receiving invoices, verifying transaction details, and processing payments.